PR1

The PR1 (Personal Robot One), along with ROS (Robot Operating System), were designed to be a powerful and versatile robotics development platform for mobile manipulation research and application development.

- Creator

- Year

- 2008

- Country

- United States 🇺🇸

- Categories

- Features

More videos

Did you know?

While testing PR1, the Stanford AI Robotics group broke the robot more than once every day for a week. That is why so much reliability engineering and testing went into PR2.

History

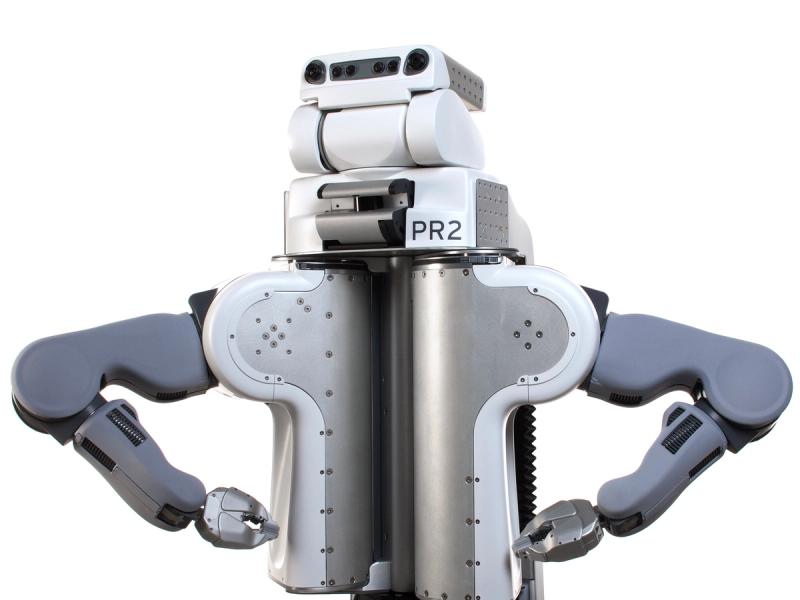

PR1 was developed by Keenan Wyrobek and Eric Berger as part of the Personal Robots Program, led by Professor Kenneth Salisbury, at Stanford University. The goal of the program was creating "platform technology for research and development where robots do mobile manipulation tasks in human environments." The first prototype mobile manipulation development platform was the PR1. Following PR1, the PR2 robot was developed at Willow Garage. The program also originated the Open Source Robot Operating System (ROS).

Specs

- Overview

Backdrivable, passive spring counterbalanced 7-degrees-of-freedom arms. The arms, grippers, head, telescoping spine, and mobile base controlled together at 1 kHz for fluid whole-body motion. Multiple onboard computers, battery system, and sensor head.

- Status

Inactive

- Year

2008

- Website

- Width

- 64 cm

- Height

- 120 cm

- Length

- 60 cm

- Weight

- 98 kg

- Speed

- 7.2 km/h

- Sensors

Force control at every joint. Videre stereo camera system in head.

- Actuators

25 motors

- Degrees of Freedom (DoF)

- 23 (Arm: 4 DoF x2; Counterbalance Adjustment: 1 DoF x 2; Wrist: 3 DoF x 2; Gripper: 1 DoF x 2; Head: 1 DoF; Torso: 2 DoF; Wheels: 2 DoF)

- Materials

Plywood and aluminum

- Compute

Two Pentium M small form-factor computers

- Software

ROS < 1.0

- Power

2 kW power system with a 4- to 8-hour runtime depending mostly on computer use

- Cost

- $50,000