UR

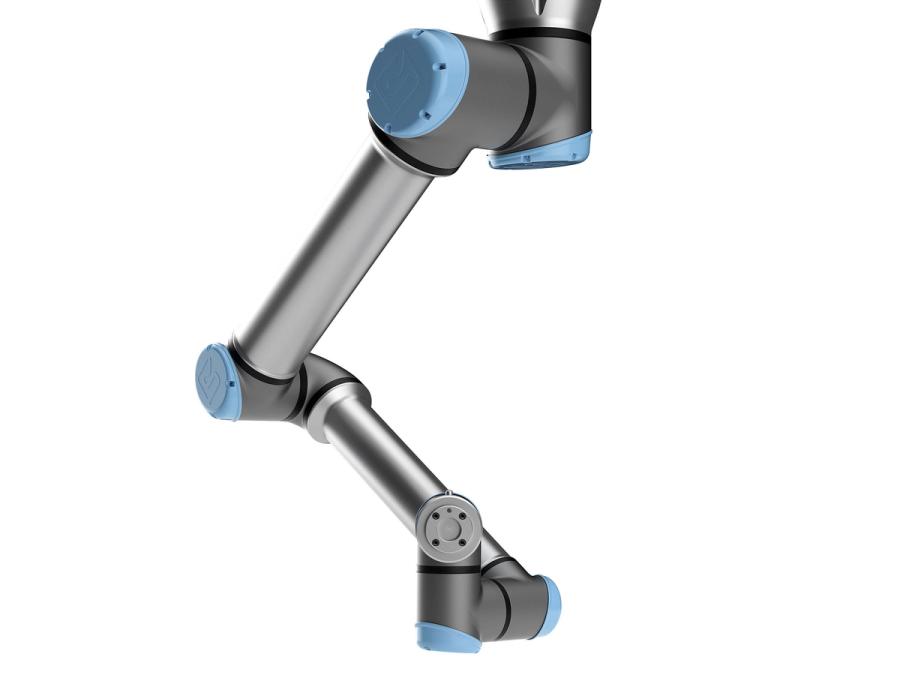

Universal Robots cobots are versatile, lightweight collaborative robotic arms designed to work safely alongside humans. Users program it through an intuitive touch-screen interface and by positioning the robot with their hands.

- Creator

- Year

- 2008

- Country

- Denmark 🇩🇰

- Categories

- Features

More videos

Did you know?

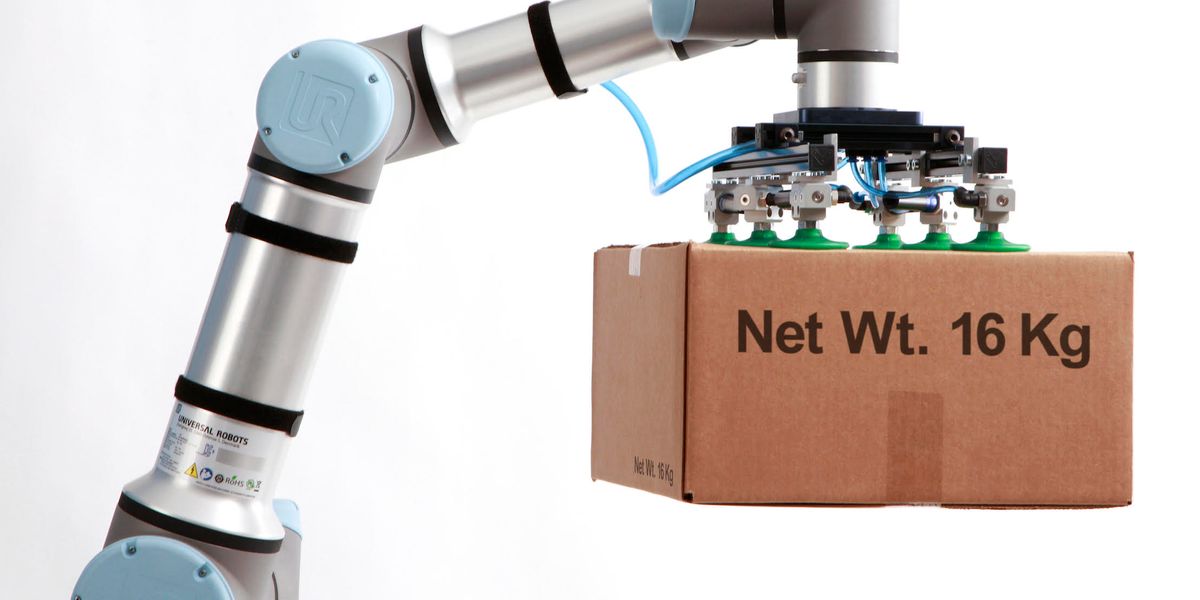

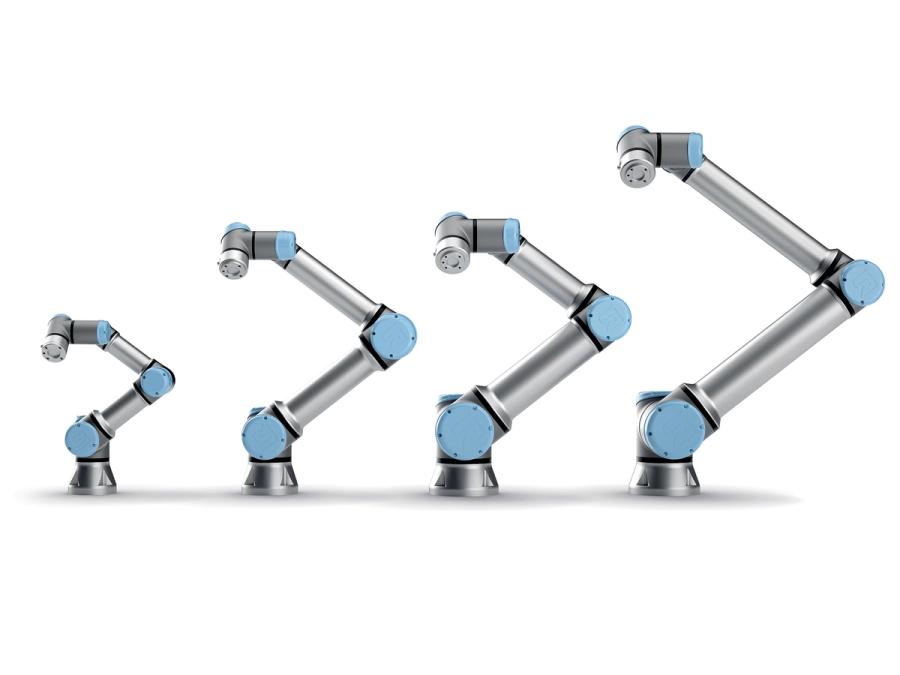

The UR cobots are named for their payload in kilograms: The UR3e, UR5e, UR10e, and UR16e can lift 3, 5, 10, and 16 kg, respectively.

History

The idea behind Universal Robots' user-friendly, inexpensive robot arms started to take shape in 2003 at the University of Southern Denmark, where Esben Østergaard was working on a Ph.D. degree. His dissertation was about how the robotics market consisted mostly of heavy, expensive, and unwieldy robots. He cofounded Universal Robots in October 2005 with financial help from investment firm Syddansk Teknologisk Innovation. The goal was to make robot technology available to companies of all sizes, especially small and medium-size manufacturers that considered automation too costly and complex. Universal Robots tested its first prototype arm in 2007 and shipped its first robot arm in 2008. In early 2015, Universal introduced the UR3, its smallest robot, which joined the UR5 and the flagship UR10, offering a payload capability of 3, 5, and 10 kg, respectively. In 2019, the company unveiled the UR16e, its strongest robotic arm, with a payload capability of 16 kilograms. Today, the company sells its products in more than 40 countries worldwide.

More Images

Specs

- Overview

New e-Series has four models: UR3e (payload of 3 kg), UR5e (5 kg), UR10e (10 kg), and UR16e (16 kg). Equipped with dual encoders, frameless servo motors, zero-backlash harmonic drives in all six joints, and a built-in force/torque sensor at the tool flange. Includes 17 safety functions, including programmable stopping time and stopping distance. Full ISO 10218-1 compliance, ISO13849-1, Category 3, PLd rating, and 30 to 50 micron repeatability. Joints are field-replaceable in under 6 minutes. Externally accessible 500 Hz system bus enabling integration with external controllers. Enables agile deployment of complex applications such as sanding, polishing, buffing, gluing, and dispensing.

- Status

Ongoing

- Year

2008

- Website

- Width

- 12.8 to 19 cm

- Height

- 50 to 130 cm (reach)

- Weight

- 11.2 to 33.5 kg

- Speed

- 3.6 km/h (arm speed)

- Sensors

Proprietary sensor for measuring electrical current in the robot's joints and determining force and movement. Force/torque sensor at tool flange.

- Actuators

AC synchronous motors

- Degrees of Freedom (DoF)

- 6 (rotating joints)

- Materials

Aluminum, ABS plastic, steel

- Compute

Custom solid-state computing and control system. Sixteen digital I/O ports, two analog I/O, 500 Hz control, four separate high-speed quadrature digital inputs, Ethernet, ModbusTCP interface, one USB 2.0, and one USB 3.0 for external equipment.

- Software

Linux OS, PolyScope programming interface on 12-inch touchscreen with mounting, ROS integration.

- Power

100-240V AC power supply, 47-440 Hz

- Cost

- $27,000 to $50,000 (approximate, through distributor)